The Analytical Process Isolator (API series) offered by Flow Sciences is designed to facilitate various processes such as weighing, dispensing, dissolution, or handling of Active Pharmaceutical Ingredients (APIs) and/or Highly Potent Active Pharmaceutical Ingredients (HPAPIs). It ensures personnel protection and provides containment measures at nanogram levels.

The enclosure is designed to accommodate various equipment, including balances, ovens, FTIR (Fourier Transform Infrared) instruments, sieves, and more. It offers adequate containment to ensure the safety and integrity of the processes being carried out.

The level of containment achieved by the API series varies based on the application and quantity of the substances being handled. It can reach containment levels measured in nanograms (one billionth of a gram) and is capable of providing containment in the Occupational Exposure Band (OEB) range of 3-5, depending on the specific application and quantity of the materials involved.

The overall design of the API series prioritizes safety and effective containment for the equipment and processes involved in handling APIs and HPAPIs, allowing for precise and controlled operations while ensuring personnel protection and minimizing the risk of exposure.

The Glovebox Workstation offered by Flow Sciences is designed to provide containment for highly toxic applications involving APIs and HPAPIs that require elevated safety standards compared to open-face enclosures. It incorporates engineered controls to prevent containment loss and has undergone third-party testing, which has demonstrated containment levels below 30ng/m³ (nanograms per cubic meter), dependent on the specific application and quantity of materials involved.

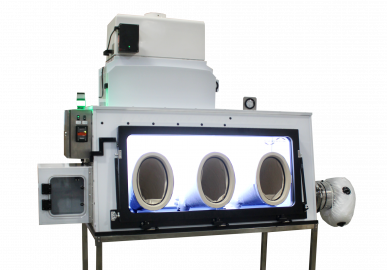

The interior of the Glovebox Workstation maintains a clean working environment that meets or exceeds ISO 5 standards for clean processing work. This is achieved through a side-mounted HEPA filter inlet that ensures the circulation of clean air within the enclosure.

The enclosure features a universal side/transfer port that provides various options for customization. These include a double-safe waste chute, continuous liner, RTP (Rapid Transfer Port) port, and more. The side port and transfer port can be positioned on either side of the enclosure. The transfer port enables the ingress and egress of materials without compromising the interior environment’s contamination control.

The construction of the Glovebox Workstation offers flexibility in viewing panels, with the option of acrylic (EGP Series) or glass (EGG Series). The superstructure is made of polypropylene, and the dished phenolic resin base is designed to contain any spills that may occur during operations.

An internal white LED light is integrated into the enclosure to enhance visibility within the workspace. The LED light can be adjusted to different angles, providing optimal lighting. Additionally, an Amber LED light option is available.

The Glovebox Workstation is equipped with a 4″ inlet HEPA filter and two sets of primary and secondary 4″ HEPA filters. The filtered air can be recirculated within the laboratory or vented out through the building exhaust system.

The enclosure features a front lift door where the glove ports are located. This door opens vertically, facilitating easy loading and unloading of equipment. The door is hinged for convenient access.

Standard sizes for the Glovebox Workstation include 5′, 6′, and 7′ foot widths, with a depth of 36″ and an internal height of 24″. Customization options are available to meet specific requirements and preferences.