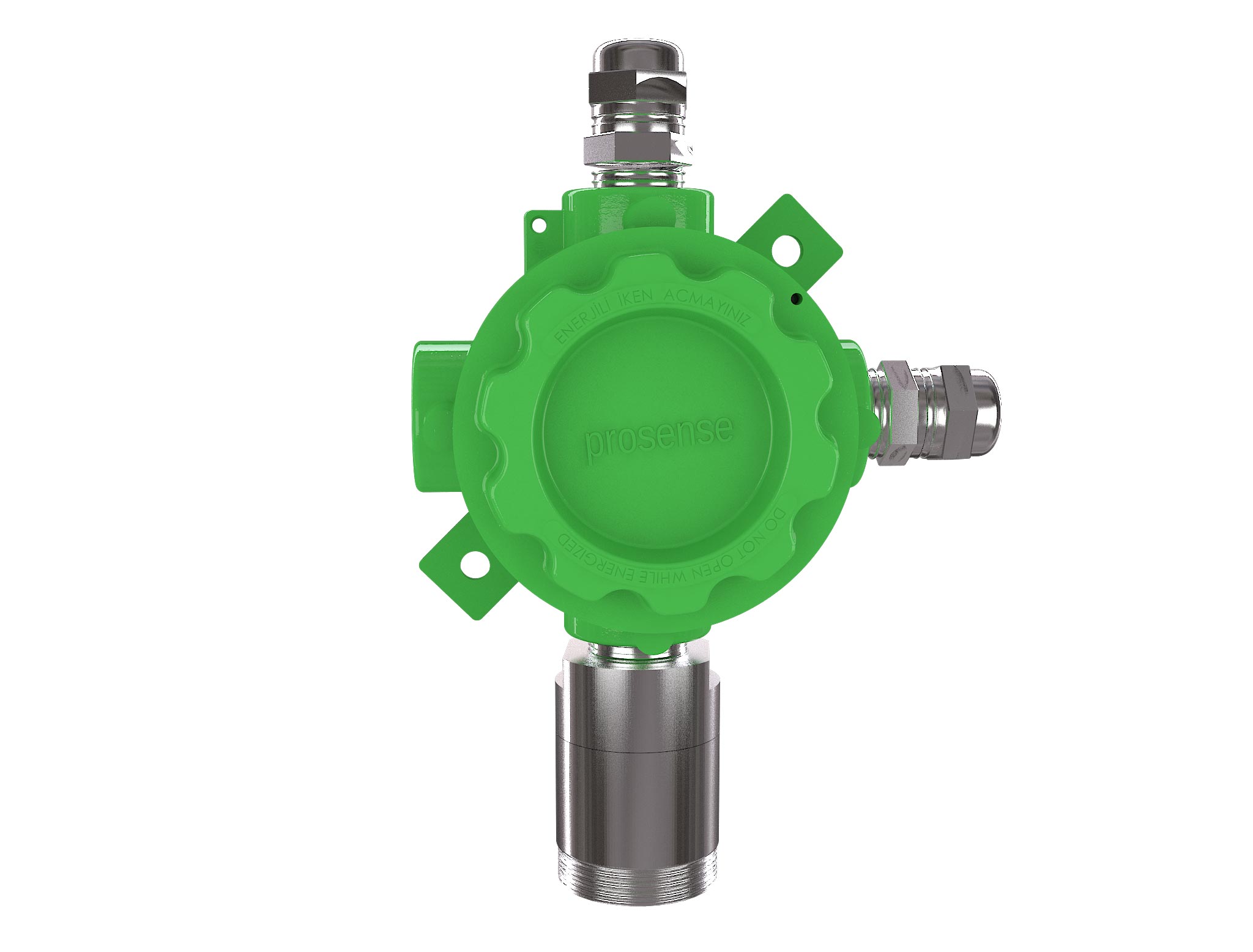

Prosense ATEX/IECEx certified “P” Series fixed gas detectors. It seems like this product is also designed to meet the requirements of various industries by providing continuous measurement of toxic, explosive, and oxygen gases in the air.

The use of different sensor technologies, such as Pellistor, Electrochemical, and Infrared, indicates that the P Series detectors are versatile and capable of detecting a wide range of gases. The ability to measure gases in different ranges, such as LEL, ppm, and VOL, is also beneficial for various applications.

The ATEX/IECEx certification of the P Series detectors ensures that they are safe to use in potentially explosive environments. It’s important to note that the certification process involves rigorous testing and evaluation to ensure that the product meets the required safety standards.

Overall, it appears that the Prosense ATEX/IECEx certified “P” Series fixed gas detectors are well-designed and suitable for use in industrial plants where continuous gas monitoring is required.

Connectivity

• Wide Range Sensors: Pellistor, Electrochemical, Infrared, Semiconductor employed P provides excellent output for the target gas.

• Modbus: P can be integrated to SCADA systems easily via open source Modbus RS485(RTU) codes

• Outputs: Different devices can be operated/controlled at the same time thanks to the 4-20mA analog, Modbus RS485 and Relay outputs

• Relay Contacts: P-3R+ relay module integrated P Series detectors can manage other equipments or link to firefighting panels.

Maintenance and Installation

• Sensor Replacement: Allows sensor replacement with pre-calibrated sensor head to provide easy maintenance.

• Installation: Designed for either wall or ceiling mounting applications

• Entry: 2 x 1/2″ NPT cable entries

• Remote Control: Detector status can be monitored Prosense Gas Monitoring software remotely.

Robust and Reliable

• Body: Aluminium die-cast body and SS316 stainless steel sensor head superb performance under harsh environmental conditions with IP65 protection class.

• Protection: Sunshield and waterproof caps are available for use in extreme conditions.

| sensor Technology | Pellistor, Electrochemical, Infrared, Semiconductor |

| Output Signal | 4-20mA and Modbus RS485 |

| Sensor Warm-Up | 60sec |

| Response Time(T90) | Sensor dependent |

| Accuracy | %1 |

| Operating Temperature | -40°C ~ +70°C |

| Humidity | 5 ~ 95%RH |

| Input | Min 10VDC – Max 32VDC – Nominal 24VDC |

| Power Consumption | Max. 4W |

| Relay Outputs | 2 Alarms (Selectable) and 1 Fault (All relays are NO/NC adjustable) |

| IP Rating | IP65 / Optional IP66 (Sensor Head) |

| Junction Box | Epoxy Painted Die-Cast Aluminum |

| Sensor Head | 316L Stainless Steel |

| Dimensions/Weight | 183×118,15x88mm / 1420gr |

| ATEX Marking | II 2G Ex db IIC T5/T4 Gb |

| Hazardous Class | Zone 1 or Zone 2 |

| Certificates | IMQ 19 ATEX 045 X IECEx IMQ 18.0009X |

| Standards | IEC EN 60079-0 IEC EN 60079-1 IEC EN 60079-18 |