Hospitals are unique environments where safety is paramount. To ensure the safety of isolation rooms, operating rooms and other specialized services, the conditions of these areas must be constantly monitored and controlled. To do this, the pressure in the room must be continuously measured and displayed. Pressure controls help hospitals and engineers comply with ASHRAE, AIA, CDC, and USP standards. Using exclusive thermal pressure sensors, TSI products provide the most accurate, reliable, and stable measurement, making them the leading choice in the industry. These products have been installed in more than 50,000 patient rooms in the world’s leading healthcare facilities, providing effective 24/7 monitoring of areas where it is necessary to protect either patients or visitors from biological agents and pathogens. If the pressure or conditions change, these devices can provide notification, alarm, or even take action by automatically resetting the pressure to levels set by the hospital’s HVAC systems. In this category page, we will explore the importance of pressure control in hospital environments, the standards that must be met, and how TSI products can help ensure the safety of patients, visitors, and staff.

A room pressure monitor is a device used to measure the pressure difference between two areas or rooms. It works by using sensors to detect the air pressure in one room and comparing it to the pressure in an adjacent area. The device can also measure the rate of air exchange between the two areas, as well as temperature and humidity levels. By monitoring these factors, a room pressure monitor can help ensure that air is flowing properly from clean areas to contaminated areas, preventing the spread of airborne pathogens or other contaminants. The device can also detect when pressure levels are too low or too high, alerting staff to take action to adjust the HVAC system or other environmental controls. Room Pressure Monitors are commonly used in healthcare facilities, clean rooms, and other environments where maintaining a controlled environment is critical.

There are several benefits to installing room pressure monitors in healthcare facilities:

Positive room pressure is a condition where the air pressure in a room is greater than that in adjacent areas. This is typically achieved by supplying more air into the room than is exhausted, causing air to flow out of the room and preventing contaminated air from entering. Positive room pressure is commonly used in healthcare facilities, clean rooms and other environments to prevent the spread of airborne pathogens.

Room pressure monitors can be used to ensure positive room pressure by measuring the pressure differential between the room and adjacent areas. If the pressure in the room is higher than in the adjacent areas, it indicates that positive room pressure is being maintained. If the pressure is lower, it could indicate that the HVAC system is not functioning properly or that there is a breach in the room’s containment barriers.

they can also be programmed to provide warnings or alarms when pressure levels fall outside a specified range, allowing staff to take corrective action to maintain positive room pressure. Some room pressure monitors can even automatically adjust HVAC system settings to maintain proper pressure differentials between rooms, further reducing the risk of contamination.

There are several different types of room pressure monitors on the market, including

The choice of room pressure monitor depends on the specific needs of the facility, the level of accuracy required, and the features and functions desired.

When selecting a room pressure monitor, there are several key features to consider, including

By considering these key features when selecting a room pressure monitor, facility managers can ensure that they select a monitor that meets their specific needs and provides accurate and reliable measurements of pressure differentials in critical areas such as healthcare facilities, clean rooms and laboratories

With a mission to provide trusted measurement, application guidance, and data analytics solutions, TSI is committed to helping its customers make informed decisions. The company’s vision of creating a better world by protecting people, products, and the environment speaks to its dedication to making a positive impact in the world. With TSI’s innovative products and focus on quality, we are confident that they are a valuable partner in our mission to protect what matters.

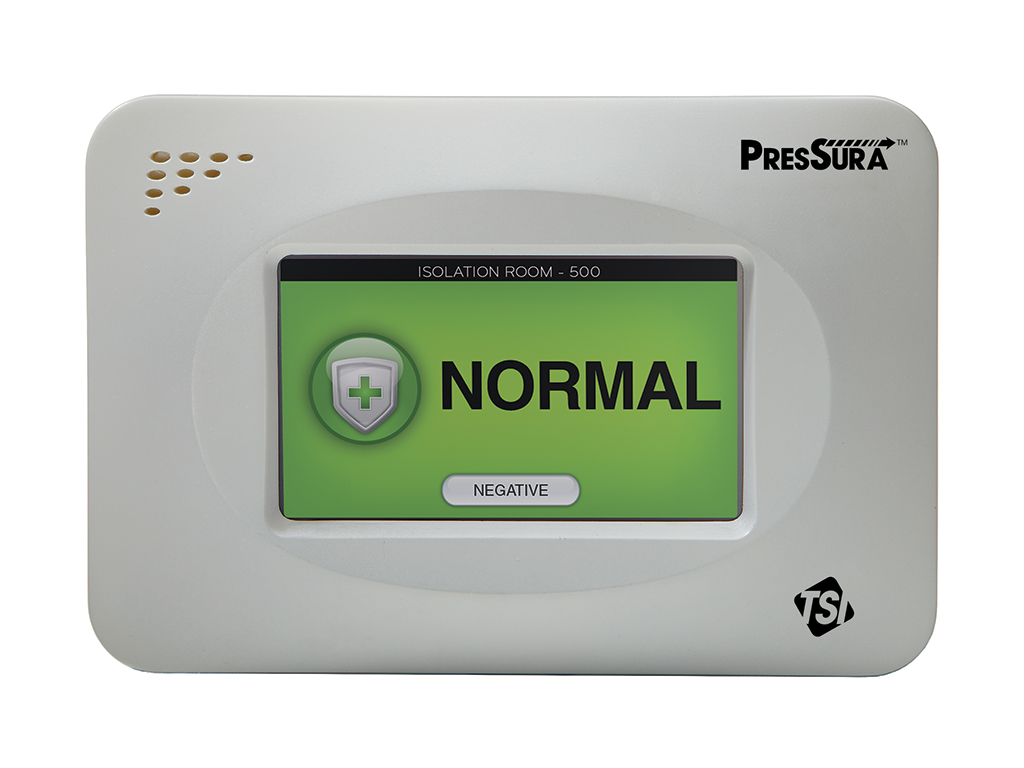

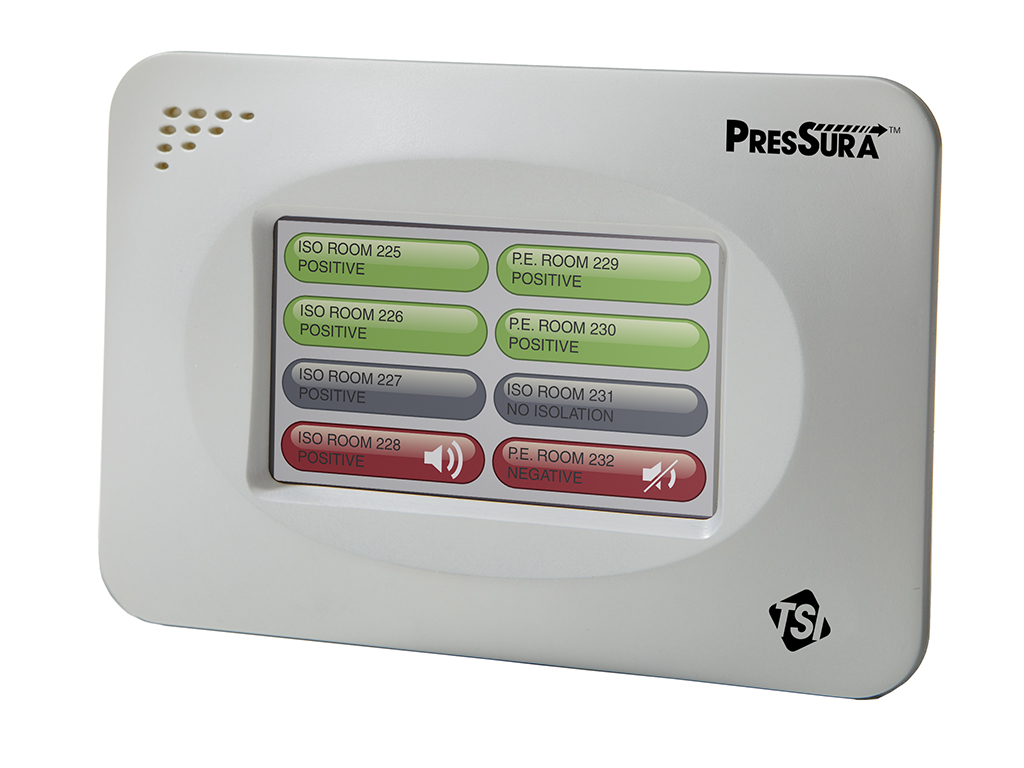

The Thermal Pressure Monitor is an advanced monitoring solution designed for controlled environments in hospitals, laboratories and other critical areas. It allows continuous pressure monitoring of isolated rooms, operating rooms, intensive care units and other specialized areas. The device offers an accuracy of +/- 10% of reading and bi-directional thermal pressure monitoring in the range of -0.20000 to +0.0200 inH2O. The unit can be seamlessly integrated into the BAS via BACnet® MS / TP, LonWorks® and Modbus communication. The unit features a 4.3″ color touch screen with intuitive operation and audible and visual alarms to alert users of unsafe conditions. It offers multiple levels of password protection for secure access and includes inputs for temperature, humidity, supply, return, pressure transducer, access door control, and room occupancy control. The unit operates on 15-40 VDC and provides 4-20 mA or 0-10 VDC analog outputs for differential pressure and 4-20 mA or 0-10 VDC control outputs for supply, exhaust and temperature. Relays and other options are also available depending on the system being installed.

This thermal pressure monitor is designed for use in controlled environments in hospitals, including isolation rooms, operating rooms, intensive care units, special laboratories and food service areas. The bidirectional monitor can be wall-mounted and is capable of continuously monitoring pressure at one or more points. It has an accuracy of +/- 10% of reading in the range of -0.20000 to +0.0200 inH2O. The RPM10 allows monitoring of a single environment and integrates seamlessly with the BAS via BACnet® MS/TP, LonWorks® and Modbus communications. The digital interface module is easy to use, with a 4.3″ color touch screen and audible and visual alarms to alert users of unsafe conditions. Multiple levels of password protection ensure secure access to driver functions based on user profile, and non-isolated mode disables alarms when the room is used with non-infectious patients or is unoccupied. The monitor has input options for variables such as temperature, humidity, inlet, outlet, pressure transducer, access door control, and room occupancy control. Analog outputs of 4-20 mA or 0-10 VDC for differential pressure and control outputs of 4-20 mA or 0-10 VDC for air supply, air exhaust and temperature are available. It operates from 15-40 VDC and has relays and other options available depending on the system to be installed.

This is a thermal pressure monitor designed for controlled environments in hospitals, including isolated rooms, quarantine areas, operating rooms, surgical suites, drug rooms, intensive care units, specialty laboratories, and food service areas. The bidirectional monitor is wall-mounted and can continuously monitor one or more points in the range of -0.20000 to +0.0200 inH2O with an accuracy of +/- 10% of reading. The RPC30 allows control and monitoring of one environment or control of three environments. It integrates seamlessly with the BAS via BACnet® MS/TP, LonWorks® and Modbus communications. The digital interface features a 4.3″ color touch screen with audible and visual alarms to alert users of unsafe conditions, and multiple levels of password protection ensure secure access to driver functions. An input for variables such as temperature, humidity, supply, exhaust, pressure transducer, access door control, and room occupancy control is available, as well as analog and control outputs for differential pressure, supply air, exhaust air, and temperature. It operates on 15-40 VDC and includes relays and other options depending on the system being installed.

Room pressure monitors play a critical role in preventing the spread of airborne disease in healthcare facilities by ensuring that the air pressure in critical areas such as isolation rooms, operating rooms and quarantine areas is maintained at a higher level than the surrounding areas. This is known as positive pressure, which creates a barrier that prevents contaminated air from entering the area and spreading to other parts of the facility. Room pressure monitors continuously monitor the pressure in these areas and alert healthcare staff when the pressure drops below the required level, allowing them to take immediate action to prevent the spread of airborne disease. In addition, room pressure monitors can monitor other variables such as temperature, humidity, and occupancy to further enhance environmental safety and control.

Room monitoring technology has a wide range of applications in a variety of industries, including healthcare, food and beverage, pharmaceutical, and manufacturing. In healthcare, it is used to monitor isolation rooms, operating rooms and intensive care units. In the food and beverage industry, it is used to monitor temperature and humidity in storage and processing areas. In the pharmaceutical industry, it is used to monitor the storage and production of sensitive drugs and chemicals. In manufacturing, it is used to monitor air quality and temperature in clean rooms and production areas. Room monitoring technology is also used in research facilities, data centers and server rooms.

Room monitors play a critical role in maintaining the quality of pharmaceutical manufacturing facilities by ensuring that environmental conditions are within specified limits. In the pharmaceutical manufacturing process, even small variations in temperature, humidity or air pressure can affect the quality and efficacy of the product. Room monitors continuously measure these critical parameters and alert operators to any deviations from the specified limits. This enables corrective action to be taken quickly and prevents the production of inferior or potentially dangerous products. In addition, Room Monitors help meet regulatory requirements by providing accurate and reliable data for audits and inspections.

Room Pressure Monitors can be integrated with HVAC (Heating, Ventilation, and Air Conditioning) systems through a Building Automation System (BAS), which allows automatic adjustment of pressure levels. The Room Pressure Monitors are connected to the BAS, which reads the pressure measurements and sends signals to the HVAC system to adjust airflow accordingly. For example, if the Room Pressure Monitor detects negative pressure in a room, the BAS can signal the HVAC system to increase the supply of fresh air to the room or reduce the exhaust of contaminated air from the room to raise the pressure level. This integration allows real-time monitoring and control of pressure levels in a facility, ensuring that pressure differentials are maintained at all times to prevent the spread of contaminants and ensure occupant safety.

When installing room monitors in a new facility or retrofitting an existing installation, there are several key factors to consider:

Tel +1 561-912-9809 / 561-9112-7201

E-mail [email protected]

6590 W Rogers Circle Suite# 11&12

Boca Raton – FL 33487

+1 561-912-9809 / +1 561-912-7201

[email protected]

6590 W Rogers Circle, Suite #11&12

Boca Raton, FL 33487